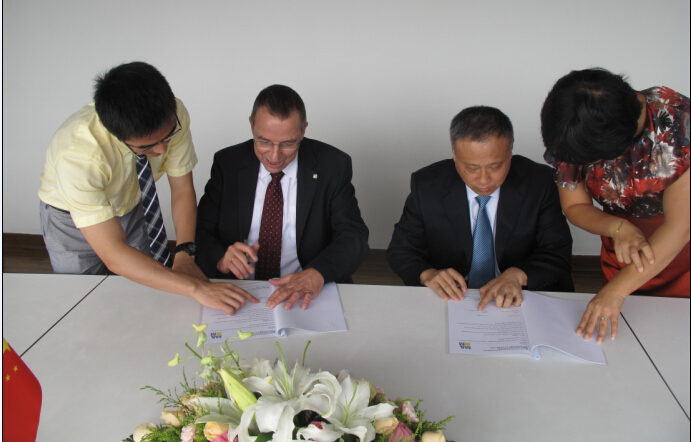

Strategic partnership signing ceremony between M&M Software and Beijing D&S Fieldbus Technology

The strategic partnership signing ceremony was held in Suzhou on July 18, 2014. Participants include Mr. Andreas Boerngen (General Manager), Mr. Jerry Zhang (Technical Director) and Mr. David Lu (Business Development Manager) from M&M Software (Suzhou) GmbH (hereinafter, M&M), Mr. Jiyang Tang (General Manager), Mr. Wen Li (Vice General Manager) and Mrs. Gena Liu (Vice General Manager) from Beijing D&S Fieldbus Technology Co.,Ltd.(Hereinafter, D&S)

Picture one

Picture two

Picture three

Both parties signed one special licensing agreement of M&M product which authorizes D&S to combine its industrial communication chip and board with DTM software, and deliver the industrial network interface products to its customers with highly integrated solution. Under this cooperation, the technical and market strength from both parties are synergized, it not only brings a new driving force for the exploration of FDT technology in China, but also sets up a best practice of protecting the intellectual property of foreign software companies operating in China. In addition, both parties believe that this cooperation would contribute to enhance the network communication capability and facilitate the data integration management of industrial automation products used in Chinese market.

M&M Software is the competent service provider for all matters concerning software products in the industrial automation. In the more than 25 years in business, M&M has gained the reputation of being a reliable partner for many renowned customers worldwide. Its vast industry know-how is reflected in a wide range of innovative and unique software solutions, and it focuses on intelligent solutions for handling and monitoring (HMI), device integration, engineering systems and web applications. Especailly, within the device integration area (EDD,FDT,FDI), M&M is a global leading player. Beijing D&S Fielbus Technology is Chinese national high-tech enterprise, it gained successful track record and enjoys high reputation at China domestic industrial automation market, including areas of industrial control network technology and PROFOBUS communication product. D&S focused on industrial network interface products and solutions, with more than 10 years of busienss operation, it has provided more than 20 thousand pieces of PROFOBUS interface board for more than 10 types of products to nearly 100 customers. D&S also established a wide market basis with PROFOBUS/Profinet gateways, and various industrial network products.

We have entered the era of digital factory, device management (asset management) is becoming necessary for various automation systems used in the factory, and accordingly data collection and management of field devices are becoming more and more important. Besides of communication capability, it requires the industrial device be equipped with data collection and integration functions. In another word, in addition of real time data communication capability for automation control, high integration of data is required for device management from automation systems as well. The emerging FDT technology rightly provides one perfect solution to address above requirements.

Picture four

FDT®(Field Device Technology) is an open standard for integration of intelligent field devices into process and factory automation systems. It defines a manufacturer-and fieldbus-independent software interface between so-called Frame Application and DTM (Device Type Manager). Frame Application can be an engineering tool, an asset management system, a DCS system, or any other systems in industrial automation. DTM is a software component for one particular field device type (or sometimes a device family), which contains all the required knowledge to configure, parameterize, or in general control the corresponding device.

Recent years, PROFOBUS technology is developing quite fast in China, especially in the power generation and petrochemical industries. Control systems in these industries require PROFOBUS-DP/V1 communication as a default standard, and tend to choose DTM as data integration interface. In order to enter large-scale automation systems, domestic device vendors are in eager need to implement their devices with PROFOBUS-DP/V1 communication capability and DTM software. D&S specialized at offering PROFOBUS interface products for many years for device vendors, and has gained solid market basis in domestic market. While M&M has been providing FDT/DTM solutions for around 10 years and established the leader position in Chinese market. The cooperation between D&S and M&M captures the requirement from domestic market by integrating the competitive advantages of both parties. This cooperation will particularly serve the technical upgrade of domestic automation device vendors better, increase their competiveness and help them to enter those large-scale automation systems at industries such as power generation, petrochemical and etc.

Picture five

Picture six

After the signing ceremony, both parties discussed how to further integrate resources and advantages of each other and made related plans as well. Both parties strongly believe this cooperation will bring win-win relationship, contribute more to the industrial automation development and upgrade of automation equipment in China.

Picture seven

Picture eight

当前位置:

当前位置: 市场客服

市场客服 在线留言

在线留言